PICTUrS,

The fight against climate change requires us to significantly reduce human CO2 emissions. In France, industrial activity accounts for around 20% of total emissions.

Industrial emissions have the advantage of being relatively concentrated and channelled. At the factory chimneys, large gas flows can be found, with significant CO2 concentrations ranging from 15% to 90%.

It is possible to separate the CO2 from the gas (mostly nitrogen, but also some oxygen and impurities). This concentrated CO2 can then be used in the food industry (to enrich air in greenhouses or in food processing) or for the production of chemicals or energy products (often in combination with hydrogen).

For captured CO2 that cannot be reused, the solution to prevent it from entering the atmosphere is to store it underground.

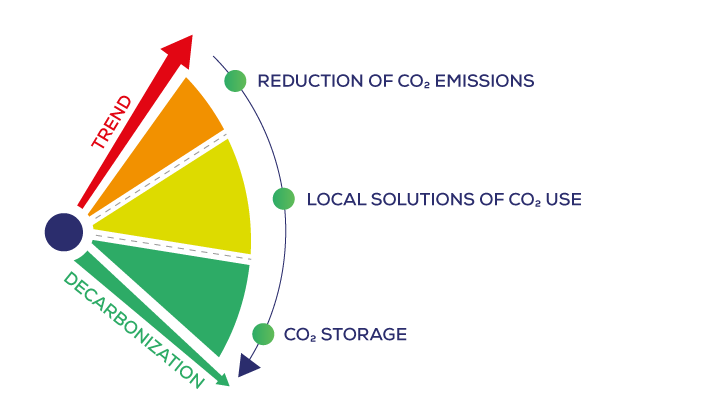

CCUS is, therefore, part of the triptych (reduce, reuse, store) that will allow industrial activity to continue while actively combating climate change.

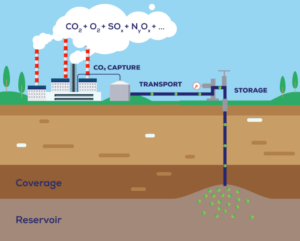

CCUS involves three main stages:

1. Capture

The separation of CO2 from other gases produced in large industrial facilities, such as power plants, steel mills, cement plants, and refineries.

2. Transport

Once separated, CO2 is compressed and transported (usually by pipeline, though ships, trains, or trucks can also be used) to an appropriate site for reuse or geological storage.

3a. Utilisation

CO2 can be reused directly or to synthesise valuable molecules through chemical or biological processes. This can produce methane, methanol, urea, building materials, and more, alongside directly reused CO2.

3b. Storage

Non-reused CO2 is injected into deep underground rock formations, at depths of one kilometre or more.

For decades, IPCC scientists have shown that human activity leads to an increase in atmospheric CO2 and, therefore, to rapid climate change. After long negotiations, governments gathered at the COP summits signed the Paris Agreement (COP 21) with strong commitments to reduce CO2 emissions.

Most industrial players, as well as numerous local authorities, have committed to achieving carbon neutrality by 2050 or even sooner. Decarbonising all our activities represents a challenge in terms of behavioural changes and the technologies we use.

To enable a socially and industrially acceptable transition, we need “buffer” solutions. CCUS, particularly its geological storage component, is a way to cushion the shock of transitioning to fully decarbonised activity.

To contribute to the Paris Agreement’s objectives, various organisations, including the International Energy Agency (IEA), the Intergovernmental Panel on Climate Change (IPCC), and France’s ADEME, have included CCUS in their overall strategy.

In Europe, several CCUS projects have already been launched to reduce industrial emissions, decarbonise hydrogen production, and transport CO2 for storage.

Further information on EU CCUS projects is available on the IEA website, the Global CCS Institute, the CCUS Network, the CCS Europe or the Net Zero Platform websites.

A programme of this scale requires a joint effort to overcome numerous challenges. The PICTUrS programme is a collaboration between many stakeholders, including 14 members of the steering committee alongside AVENIA, such as ArcelorMittal, Baker Hughes, BRGM, the Communauté d’Agglomération de Pau Béarn Pyrénées, CTP, Geostock, IFPEN, Lafarge, Repsol, SLB, Sofresid, Teréga, and UPPA.

The programme aims to contribute to the energy transition by reducing industrial CO2 emissions.